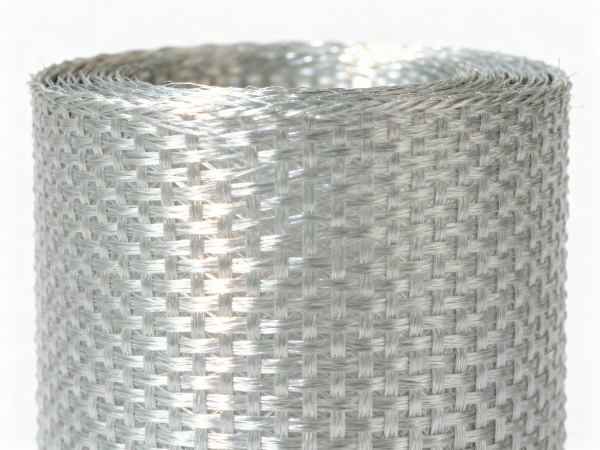

Fiberglass Reinforced Plastic (FRP) is a composite material made by combining a polymer matrix with fiberglass strands. This fusion creates a lightweight yet durable material that boasts an impressive strength-to-weight ratio. FRP is commonly used across various industries such as automotive, construction, aerospace, and marine due to its ability to resist harsh conditions while maintaining a relatively low weight.

The strength of FRP is largely influenced by its composition and manufacturing process. Typically, the material’s strength ranges between 50,000 and 150,000 psi (pounds per square inch), which is comparable to or even exceeds that of many metals. This makes it ideal for applications where both strength and lightness are critical.

FRP offers several advantages over traditional materials like steel and aluminum. One of the key reasons to choose FRP is its exceptional strength-to-weight ratio. This means that for the same amount of material, FRP can provide greater strength while remaining much lighter than metals.

Additionally, FRP's corrosion resistance makes it ideal for use in environments exposed to moisture, chemicals, or extreme temperatures. Unlike metals, which can rust or corrode over time, FRP retains its strength and structural integrity, even when exposed to harsh conditions such as saltwater or industrial chemicals.

Another advantage is ease of fabrication. FRP can be molded into complex shapes and sizes without compromising its structural strength. This makes it highly adaptable to custom designs, providing versatility for designers and engineers across industries.

FRP’s versatility is reflected in its wide range of applications. Here are some of the key industries where FRP is commonly used:

When compared to traditional materials like steel and aluminum, FRP often proves to be stronger in certain respects, especially when factoring in weight. Steel, for example, has a higher tensile strength but is much heavier than FRP, making it less efficient in applications where reducing weight is essential. On the other hand, FRP’s lightweight nature allows for easy handling and reduces the overall load on structures or vehicles.

For instance, in the aerospace industry, where every ounce matters, FRP’s strength-to-weight ratio makes it a preferred material over traditional metals. Similarly, in automotive design, using FRP for components can lead to significant weight savings, improving both fuel efficiency and performance.

However, it's important to note that while FRP excels in strength-to-weight performance, materials like steel and aluminum may still be better suited for applications requiring maximum load-bearing capacity in extreme conditions.

One of the most compelling reasons to choose FRP is its long-lasting durability. FRP is highly resistant to environmental stressors like UV radiation, moisture, and extreme temperatures. Unlike metals, which can corrode over time, FRP retains its structural integrity even in the most demanding environments.

Its low maintenance needs also contribute to its durability. For example, in the marine industry, FRP boats are able to withstand exposure to saltwater without rusting, making them a cost-effective choice for boat manufacturers and owners.

In construction and infrastructure, FRP-reinforced concrete is a popular option for its longevity. The fiberglass strands within the FRP act as a reinforcement that helps prevent cracking, offering a solution that can last for decades without significant degradation.

FRP offers several key advantages for structural applications:

In structural uses, whether it’s reinforcing a building or creating components for an automotive or aerospace application, FRP’s unique combination of strength, weight, and durability ensures that it remains a popular choice for engineers and manufacturers.